THE POWER OF OUR

In the Mechanical, Electrochemical and Process sectors, it is essential to reconcile the solidity of the expertise gained in the field with a dynamic approach in step with the times, given by constant training.

High level skills:

we guarantee a flexible structure in the execution of the various operational workflows, at the same time as a rigid constitution based on persistence in the sector.

This dualistic constitution, developed over the years, allows us great credibility and security in dealing with daily work.

Our main activities we deal with:

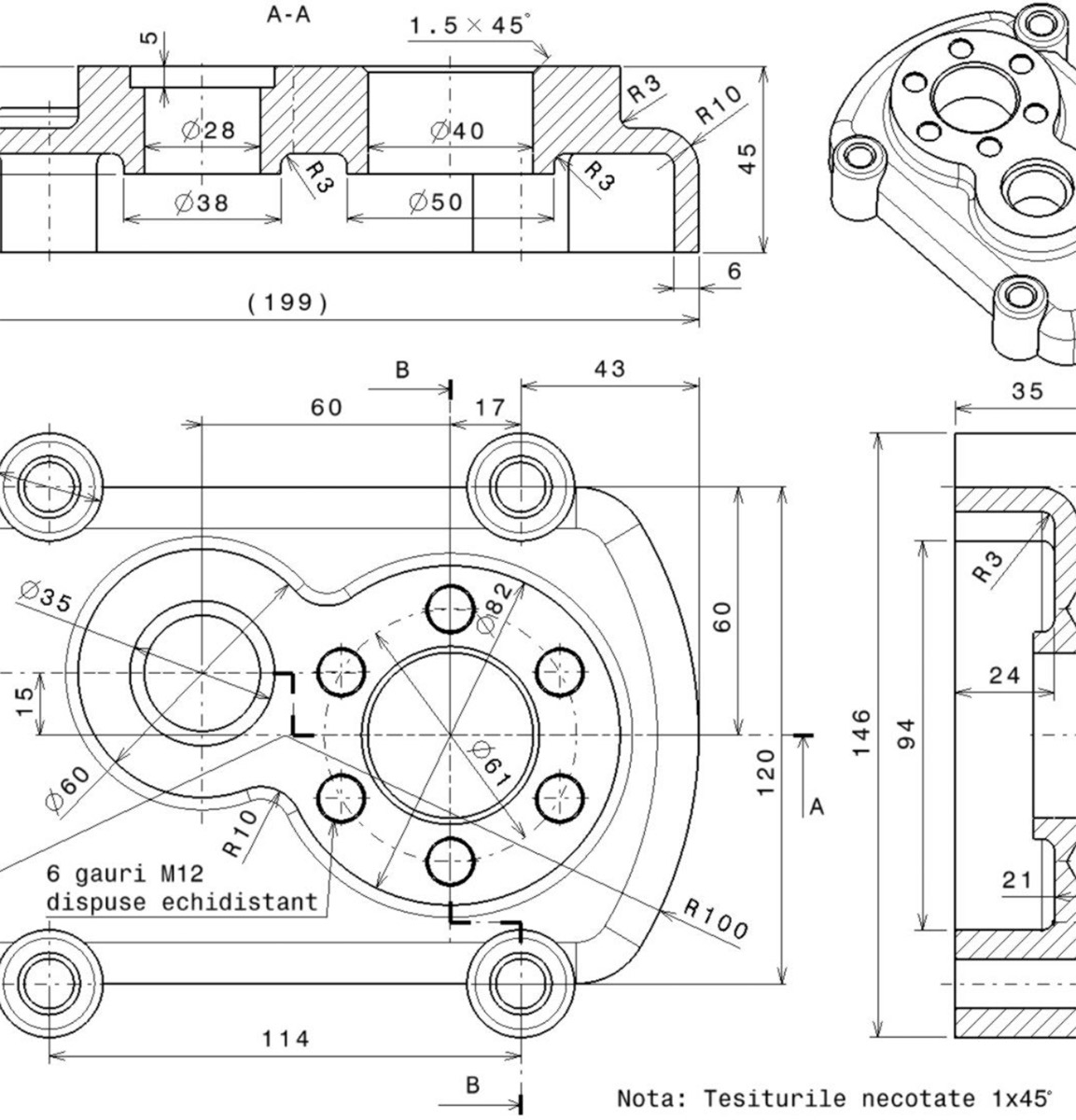

1. Sizing and pressure vessels calculation (ASME VIII div. 1, 2019, EN 13445, AD 2000)

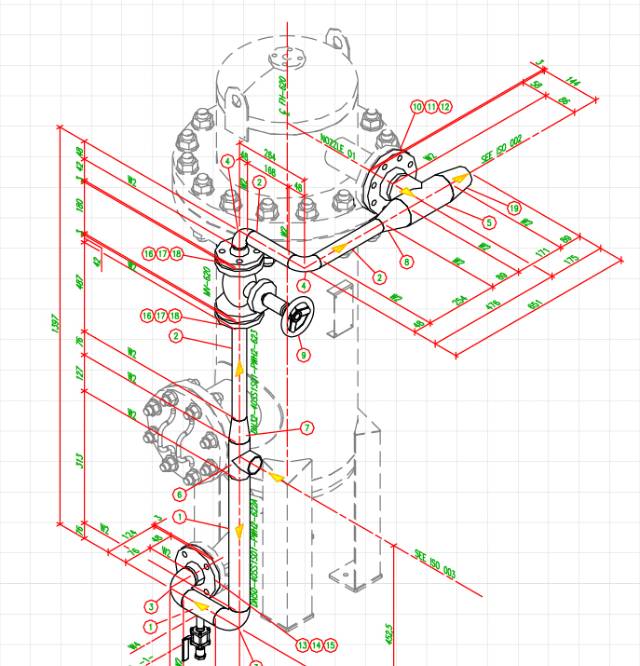

2 Sizing and piping calculation (EN 13480)

3. SKID drawing and structural verification

4. Inspections and audits

5. Staff training

6. Suppliers Surveillance

7. Welding Procedures Qualification EN 15614, EN 14732

8. Welders Qualification EN 9606

9. technical specification draw-up

10. Structural calculations

11. Non-destructive test EN 9712

The multiplicity of fields of intervention is possible thanks to our professional network, which allows us to propose a dedicated Project Manager who personally manages all progress, monitors the work segments and supports the client in the strategic phases.

In our network:

2D / 3D technical drawing offices

Finite Element Verification Office (FEM Calculations)

Prototype realization

CFD realizations office

Sizing and verification office for heat exchangers

Office for checking / analyzing stress on pipes with Bentley® AutoPipe

* Bentley® AutoPipe: advanced and complete tool for pipe stress analysis in accordance with the main European and international codes.

For inspections & expediting activities in collaboration with:

Thanks to the coordination and dialogue with a single interlocutor, we are able to guarantee a wide range of services.

Step 1

Customer request.

Data acquisition,

information and documentation

Step 2

Data processing.

Classification of the request.

Step 3

Project workflow implementation.

Operation on the project.

Step 4

Processing of the results.

Drafting of a certificate of conformity.

Submission for validation.

Step 5

Delivery of documentation and certificate.

Design

A good project is the basis of everything.

Our approach to Design is the respect of the recent directives in terms of safety and quality.

The documents produced by our professionals are defined as “reliable” in the broadest sense of the term because they are subject, before reaching our client’s desk, to a rigid internal verification and validation process.

Technical Activity

A team at your disposal, with the convenience of a One-to-One dialogue.

The process management method from a technical point of view is based on a constant individual presence of our Management assets: the orders we take on are managed continuously by the same staff, which proceeds according to strict and consolidated parameters.

The contact and referent are always the same: it will be your main vehicle to monitor and be involved throughout the collaboration.

The technical activity provided is not limited to the management of processes, but we also intervene – on request – to optimize product design strategies: we have

the competence to expose ourselves to give suggestions, advice and best practices to get the best from the market.

Certifications

In collaboration with notified body:

APAVE Italia CPM (NoBo 0398)

PED – 2014/68/UE

SPVD – 2014/29/UE

EN 9606 – 1÷5

EN 15614

EN 287 – 6

EN 14732

SOME

APPLICATIONS

OUR

Contacts

Address

via dei Mulini 6, 26845 Codogno (Lodi), Italy

Phone Number

+39 370 340 4112

Italiano

Italiano Deutsch

Deutsch Français

Français